High-temperature ceramics sounds like the latest trend in cookware.

But unless you plan to bake a cake at 4,000 degrees Fahrenheit, these new-age materials are better suited for supersonic jets and advancements in aerospace technology.

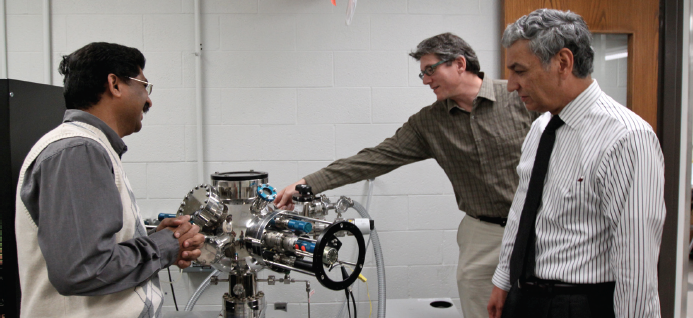

Arturo Bronson, Ph.D.; Jack Chessa, Ph.D.; and Chintalapalle Ramana, Ph.D., sat around a conference table in the Engineering Building on The University of Texas at El Paso campus to discuss the state of materials science.

high-temperature coatings. He collaborates with Arturo Bronson, Ph.D., right, and Jack Chessa, Ph.D.,

to develop coatings designed to withstand temperatures hot enough to liquefy steel.

The scientists talked about some of their latest collaborations: projects that test the limits of materials, including coatings designed to withstand temperatures hot enough to liquefy steel.

“We work as a team but with entirely different contributions,” said Chessa, associate professor in UTEP’s Department of Mechanical Engineering. “And collectively we do more than the sum of the work.”

In the last four years, that work has included a dozen high-temperature materials research projects and more than $1.5 million in grant and contract funding from the Air Force Research Laboratory and the Air Force Office of Scientific Research.

Improving the high-temperature capability of materials and coatings is key to aerospace advancement – especially as agencies push for faster, more powerful and more efficient systems.

“There are not a lot of universities – period – working on these types of materials,” Chessa said. “This is just brilliance in the foresight and serendipity of our working relationship.”

Bronson works with the chemistry and experimental side of high-temperature materials. Chessa works with the computational components for theoretical aspects of high-temperature materials. Ramana, assistant professor in UTEP’s Department of Mechanical Engineering, works with fabricating and manufacturing high-temperature ceramic coatings.

“In the major thrust materials program, they look for novelty,” Ramana said. “It’s the entry into the Air Force (research world).”

As aerospace companies discovered in the 1950s, increased operating temperatures for turbine engines caused excessive oxidation of materials, including high-strength nickel- and cobalt-based super alloys. The need for speed was surpassing the materials’ capabilities.

“In 1987, the Air Force awarded UTEP a proposal to participate in a workshop to determine which materials would be pursued in the future,” said Bronson, professor in UTEP’s Department of Mechanical Engineering.

Since then, UTEP has played a consistent role in Air Force materials research.

The Air Force Research Laboratory (AFRL), headquartered at Wright-Patterson Air Force Base in Ohio, leads the discovery, development and integration of affordable war-fighting technologies for America’s aerospace forces.

The Air Force Office of Scientific Research (AFOSR), a component of AFRL, manages the Air Force’s basic research proponent. According to the AFOSR website, about 75 percent of the research is conducted in academic and industrial settings.

“UTEP has had a long relationship with the U.S. Air Force Research Lab and AFOSR,” said Roberto Osegueda, Ph.D., UTEP’s vice president for research. “In the mid-’90s the AFOSR invested in UTEP for the creation of the FAST Center for Structural Integrity of Aerospace Systems. Through the years, the research funding has continued for multiple projects that have provided many opportunities for our students and our faculty.”

Ramana is receiving accolades from AFRL civilian and military personnel for his advancement of high-temperature materials – both in project form and in spurring participation among his undergraduate and graduate students.

“I thought the work of Dr. Ramana was outstanding,” said Tobey Cordell, program manager with Universal Technology Corp., a private company working with AFRL to offer specialized support for aerospace systems and technology. “In terms of his active involvement with the Air Force’s Minority Leaders Program, Dr. Ramana has served as a model for other professors and other schools.”

Ramana notes that helping to provide solutions for Air Force materials and participation from the next generation of material scientists has been well received by the Air Force.

Cordell praised Ramana’s participation with the AFRL – he attended events with his students at the lab in Dayton, Ohio, to provide guidance and worked with contract-funded research that has consistently led to ongoing explorations of high-temperature coatings for aerospace advancements.

Ramana was recently selected to participate in the 2012 Air Force Summer Faculty Fellowship Program.

“I am extremely pleased with the current efforts of Drs. Chessa, Bronson and Ramana, not only for the research deliverables to the U.S. AFRL but also, and especially, for providing research experiences to our students at AFRL facilities,” Osegueda said.

More than 150 UTEP undergraduate and graduate students have participated, visited, presented or interned with the AFRL. As one of the premier labs in the nation, AFRL is providing students a firsthand look at what the Air Force is doing.

“AFRL is extremely impressive,” said Manuel Hernandez, a UTEP mechanical engineering master’s student who interned at AFRL during the summer of 2011. “In one lab are the most scientists and engineers I have ever seen in one place. AFRL and UTEP were able to show me the way to be a better researcher.”

The research does not come without competition, Chessa said. He noted that UTEP faculty members have beat out other top-ranked universities for research funding.

“This research is a stepping stone to what we want,” Ramana said. “It’s shows that we (at UTEP) are capable of Tier One research.”